Integrated Solutions

At Rilesa, we understand that one size doesn’t fit all in woodworking. That’s why we offer a unique approach. Imagine having the ability to tailor your production line to fit the exact needs of your project. You’re not limited to predefined setups; instead, you have the power to choose from our diverse range of machines and create a combination that perfectly suits your requirements.

Precision Crafting

Tailor your woodworking with pinpoint accuracy. Our diverse machine range ensures each project detail is executed precisely.

Material Handling

Seamlessly integrate material handling for streamlined operations. Minimize manual intervention, optimizing efficiency with our integrated solutions.

Effortless Workflow

Streamline production seamlessly. Our machines integrate flawlessly, optimizing every woodworking step for enhanced efficiency.

Crafting Your Woodworking Future

Explore our tailored solutions, where you shape your woodworking journey. Choose from a variety of machines to build a lineup uniquely yours. Check out some examples below and envision the possibilities for your projects.

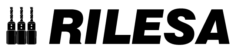

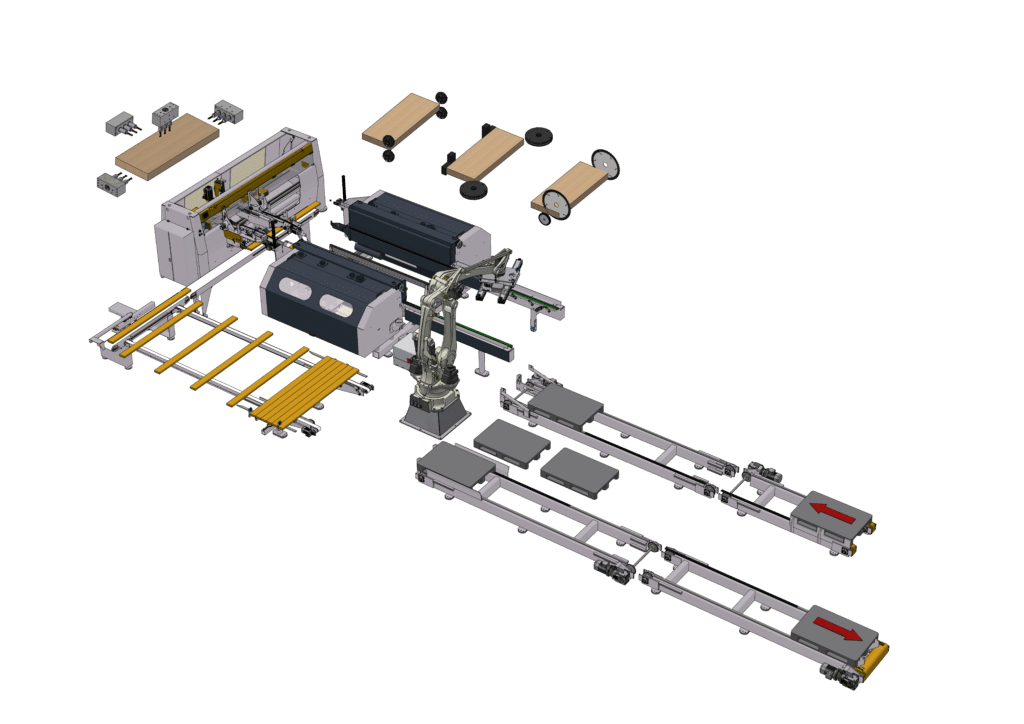

6 SIDE DRILLING LINE

1. Robot infeed/outfeed

2. 3 Side drilling

3. 180° turning unit

4. 3 side drilling line

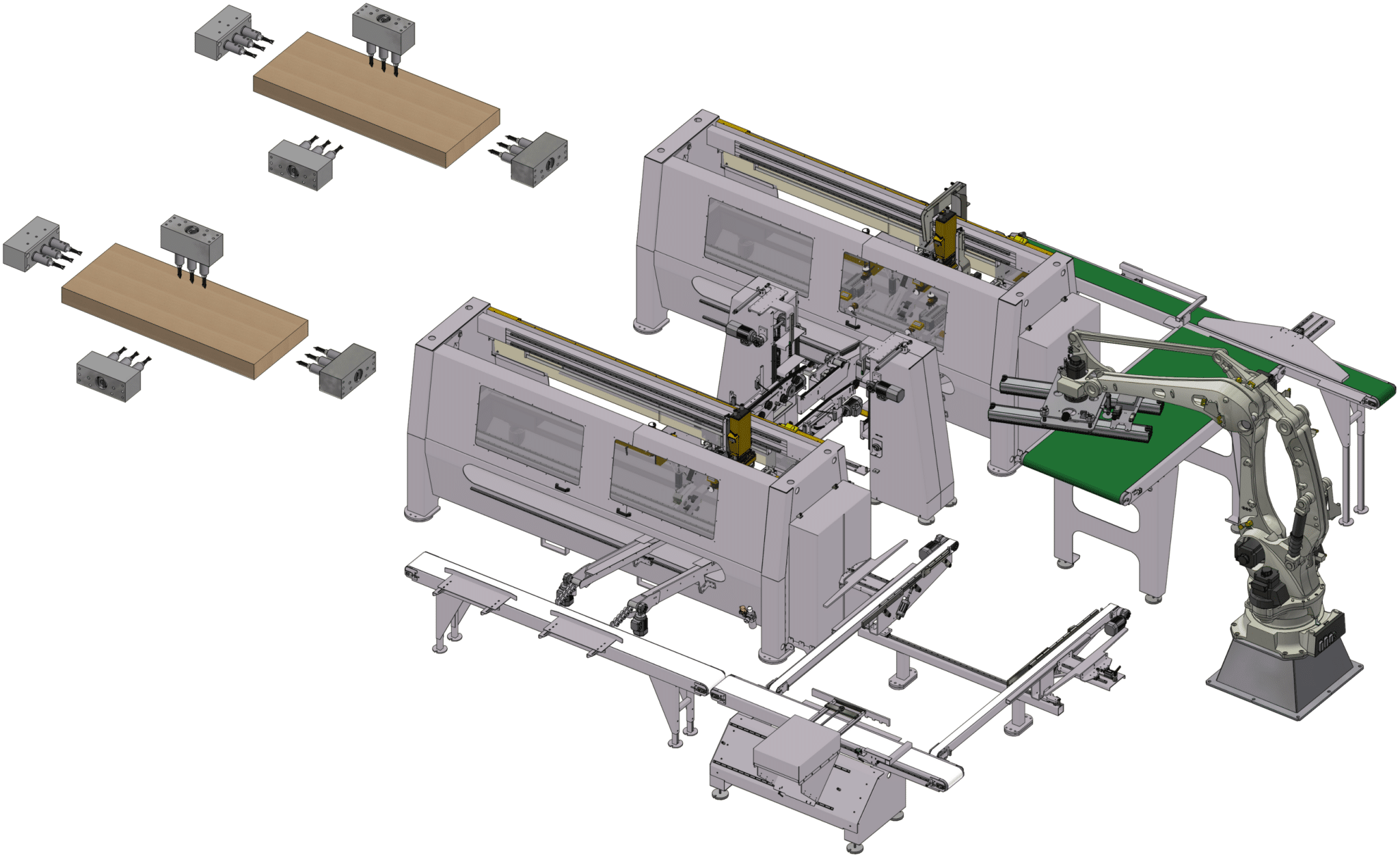

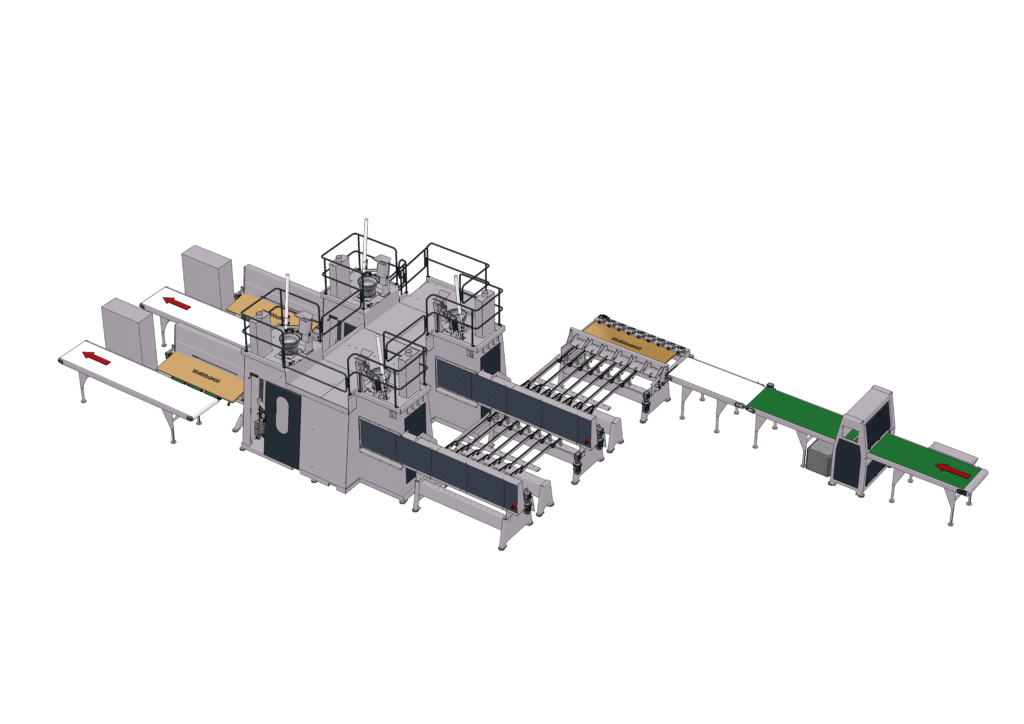

LINE FOR BOX MATTRESS

1. Length cutting with scoring

2. 2 axis CNC milling (slots)

3. 2 axis CNC milling (radius)

4. 2 axis slot milling

5. 180° turning unit

6. Drilling

7. T-Nut inserting

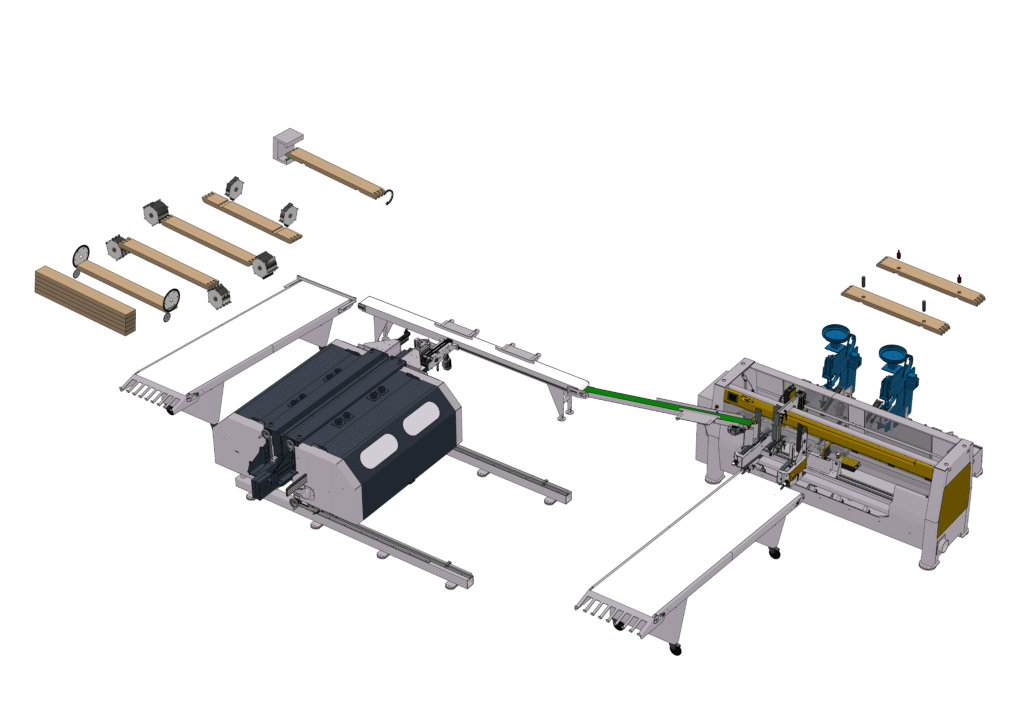

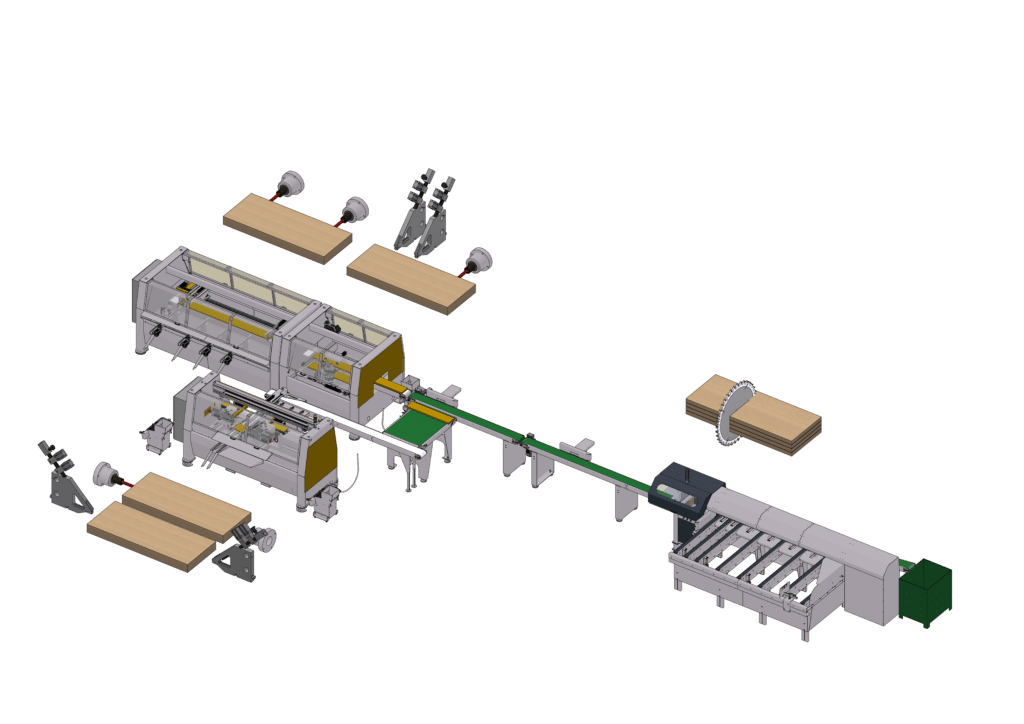

LINE FOR DRAWER BOX

1. Length cutting

2. Drilling double layer

3. Splitting with scoring

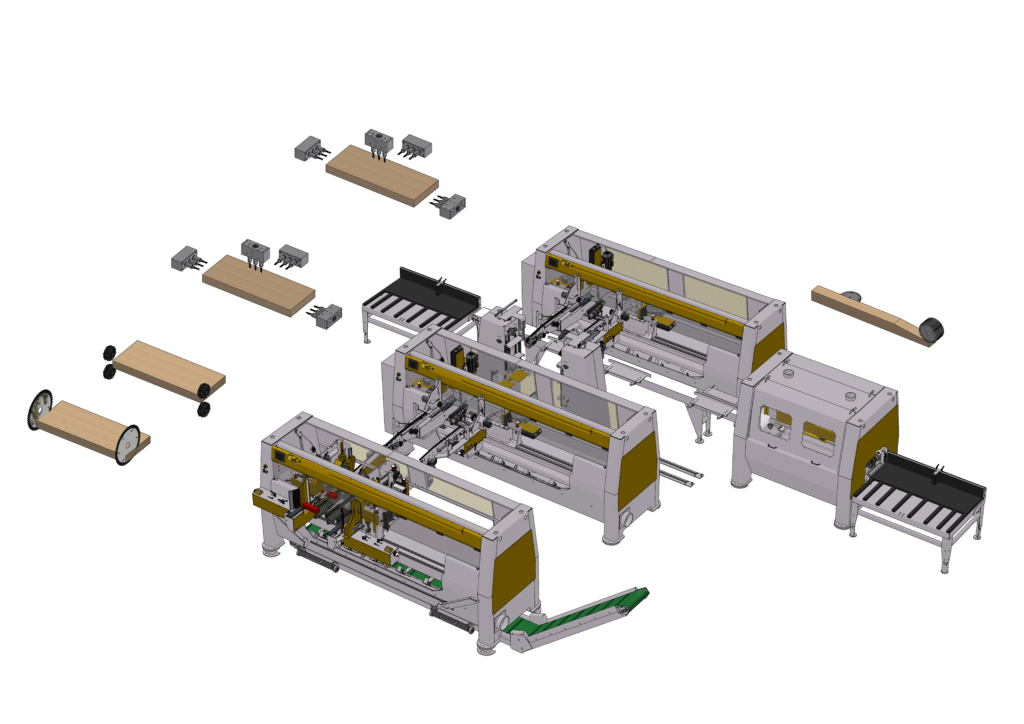

LINE FOR FURNITURE PARTS

1. Robot infeed/outfeed

2. Length cutting with scoring

3. 3 axis CNC milling

4. 2 axis CNC chamferring

5. 3 side drilling

LINE FOR GLUEBOARD REPAIR

1. 2 Side defect scanning with AI machine learning

2. 2 x 3 axis working unit (front and back side)

– Knot drilling -> glue insertion -> wood plug insertion

– Boat milling -> glue insertion -> wood boat insertion

3. 2 x 3 axis working unit (front and back side)

– Knot drilling -> glue insertion -> wood plug insertion

– Boat milling -> glue insertion -> wood boat insertion

LINE FOR DOOR PRODUCTION (BATCH SIZE 1)

1. Length cutting

2. 1 Axis CNC controlled drilling

3. Inserting of RFID tag and wood dowel

4. CNC controlled drilling (LH and RH sided)

5. CNC controlled drilling and doweling

LINE FOR FURNITURE PARTS

1. Length cutting

2. 2 axis chamfer unit

3. 3 side drilling

4. 3 side drilling

4. On/off slot milling with 2 axis CNC milling